Solution to manage your Logistics Operation

With Atlante WMS, gain more control and simplicity in managing your company's materials.

Some of our clients

Get to know some of the clients and partners we have had the privilege of working with so far. Their success stories are our pride and a testament to the quality of our services.

Efficiency for your material management beyond your imagination!

Control your inventory, save money, and optimize your processes with smart logistics!

- Cost Savings on Purchases

- Reusability

- Tracking

- Localization

ENHANCED EFFICIENCY

We simplify complex processes, saving you valuable time and resources.

TOTAL CONTROL

Gain complete control over your inventory and materials, enabling more precise and confident decision-making.

ERROR REDUCTION

Minimize operational errors, ensuring your materials are managed with accuracy.

CUSTOMIZED SOLUTIONS

We address the unique challenges of your business, delivering tailored solutions to meet your specific needs.

LOGISTICS OPTIMIZATION

Streamline and enhance your logistics management for a more efficient and cost-effective experience.

ACCESS CONTROL

Assign privileges to your operators for managing their respective warehouses.

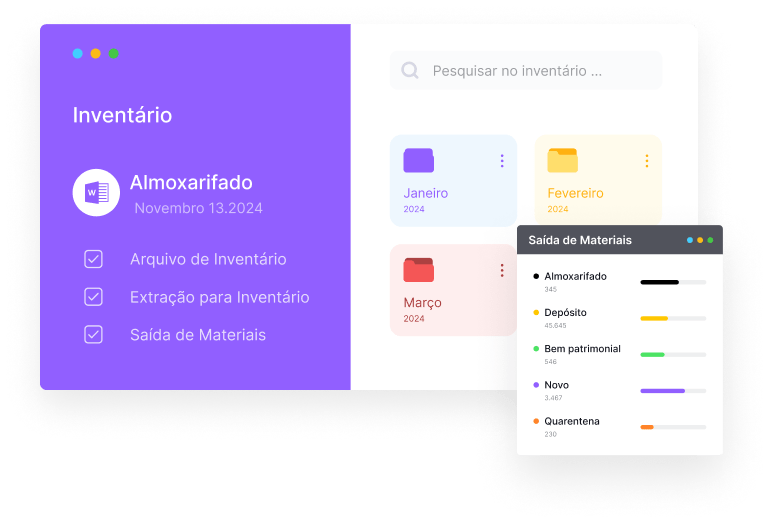

How SAL enhances the efficiency of your operation

Atlante is a robust Warehouse Management System (WMS) solution delivered in the form of Software as a Service (SaaS). It has been meticulously designed to provide total control over material management, enabling process optimization and simplification.

We firmly believe that people are essential to any process. That’s why we invest in dedicated development teams responsible for implementing the necessary customizations for the client’s environment. These teams are committed to continuously enhancing the WMS to meet the company’s needs.

We understand that the true success of a project is only achieved through collaboration. That’s why we present eadLog, a powerful e-learning platform filled with cutting-edge content related to the world of Supply Chain.

What can SAL do for your business?

Optimize your resources and boost your company’s efficiency with our Material Management System: the complete solution for intelligent asset control.

How Sal Solutions Helps Optimize Your Operation

With our solution, you’ll have complete control and access to all the information about your materials, enabling you to make the best decisions to balance inventory while considering demand and supply capacity.

- Material Transactions

- Reverse Logistics

- Addressing

- Repairs

Frequently Asked Questions

Is it possible to track materials?

Yes, it is possible to identify all transactions of a specific item, including details such as the date and the person responsible for the transaction. We often say that we provide complete item tracking.

What warranties are provided for repaired materials?

There are contracts established between the company and the repairers, which define the warranty terms for the items. The application manages warranty control, ensuring that items under warranty sent back to the repairers are not charged by them.

What inventory visibility options are available?

It is possible to identify items that are: In stock (warehouses) - In transit during transfer processes - Held by technicians - Set aside for repair - With repair service providers - Allocated to vehicles - Installed at sites, buildings, or residences.

How are materials used in service orders controlled?

How are materials used in service orders controlled? During the execution of a service order, various pieces of information are recorded, including: Service order number - Person responsible for execution - Reason for the request - Description of the tasks to be performed - Execution date - Execution location - Observation area - Services and materials used (if applicable) This detailed tracking ensures proper control and accountability for all materials and services involved.

How is material addressing done?

One of the most common methods is geographic orientation through signage, which essentially uses streets, numbers, aisles, and floors within the warehouse, similar to the addressing system in residential neighborhoods. Each company typically has unique characteristics and specific requirements for material management, so warehouse addressing may not always follow a single standard. Therefore, it’s crucial for managers to identify these needs and define the best systems for planning, organizing, and identifying their sections. To better illustrate, here are some of the most common and widely used inventory addressing systems: By area - By aisle - By level - By bay Once the storage system is chosen, it can be configured in our application to precisely match the intended design, ensuring alignment between expectations and execution.

How about letting us help you improve your material management?

Join leading companies that have already mastered efficient, reliable, and secure material management.

Fill out the form and get a free demo!

I want to speak with a consultant

Complete system to manage your inventory!

Terms of Use

Privacy Policy

Get in touch:

- Av. Brigadeiro Faria Lima, 3729 - 5º andar - Itaim Bibi